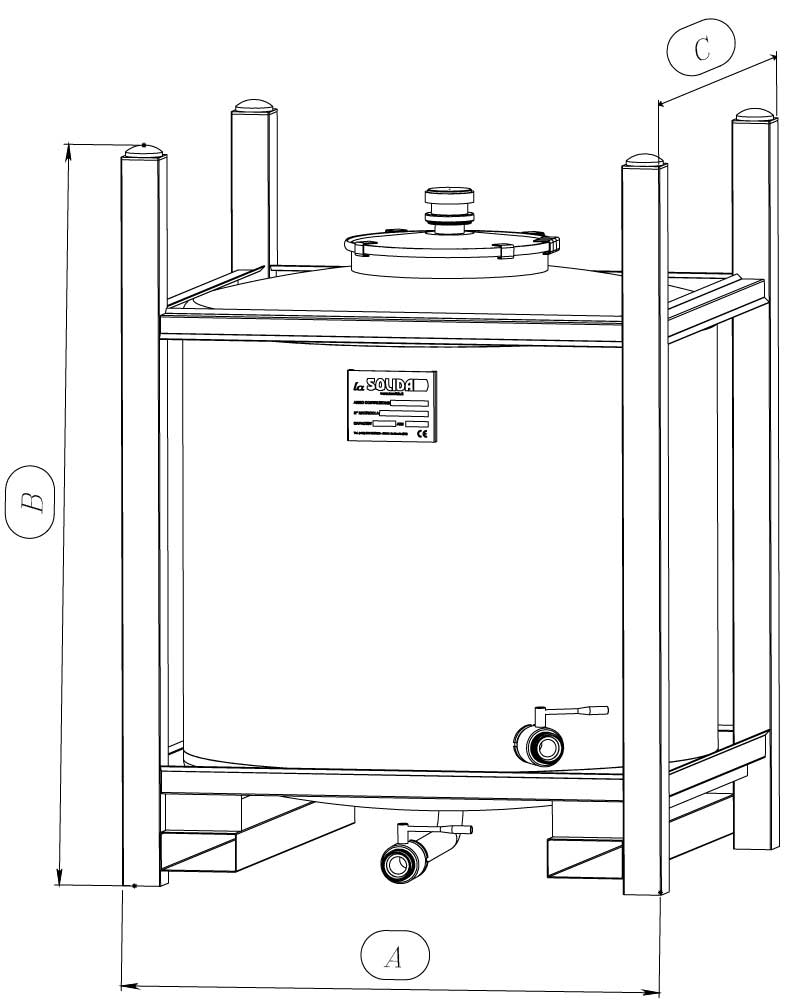

Palletized handling tanks

Palletized handling tanks

CHARACTERISTICS

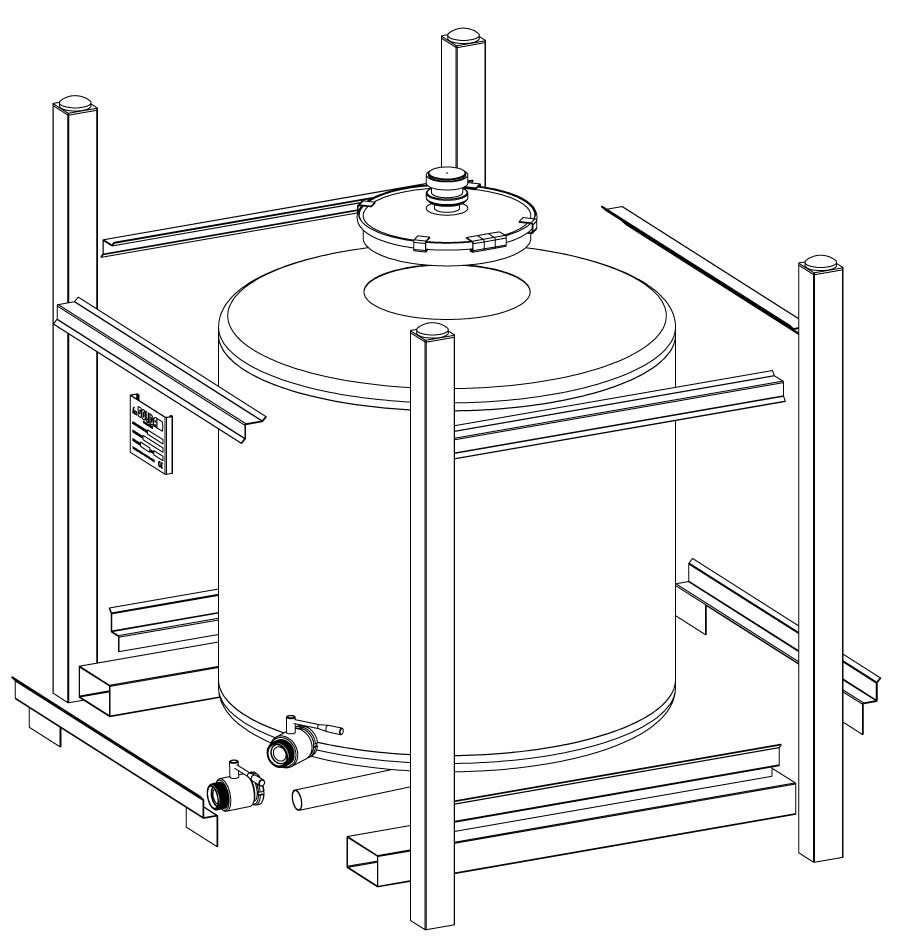

Classic circular shape resting on the ground on adjustable legs for perfect positioning. Conveniently accessible thanks to a door positioned on the front and easily loaded from above by means of a manhole cover. It is normally supplied with the most important accessories that allow you to check the height of the liquid level, the temperature, the sampling and the complete discharge of the contents. Classic finish with external flourishing and glossy internal surface for perfect compatibility with food.

BENEFITS

Efficiency is the word that sums up this tank, thanks to it you can afford excellent use of space in the cellar and outside. Extremely convenient for decanting that exploits gravity, giving a lower mechanical impact to the wine. Thanks to the external structure and the steel tank, storage will be convenient and safe, requiring very little maintenance. Hidden corners and edges reduced to a minimum to be able to excel also in the external cleaning of the tubular cage.

Perfect for storing food liquids. Moving is made comfortable, easy and safe with the presence of accommodation dedicated to handling with forklifts. Unique of its kind, if you want to stack one tank on top of the other, all this will be possible, allowing safe operations. Easy to fill and empty thanks to the connections on the top and bottom of the tank.

External surfaces

Internal surfaces

External welds

Internal welds

External welding accessories

- Recommended for its easy internal washability and unmistakable aesthetic characteristics.

- Finishing normally essential for easy cleaning and homogeneity of shape.- Le differenti tipologie di finitura rispetto a quelle sopra citate è sempre possibile combinarle alle vostre esigenze estetiche e tecniche specifiche.

- It is always possible to combine the different types of finishing with respect to those mentioned above to your specific aesthetic and technical needs.

- Specific material for its high resistance to corrosion.

- The difference in the material used derives from specific preservation of particular contents, or from placement environments requiring even higher corrosion resistance capabilities

The double effect avoids major damage and risk of implosion.

Essential for viewing the contents of the tank.

It avoids air bubbles and guarantees solidity.

It identifies the tank and communicates its main data.

Makes moving with forklifts easier.

Allows partial emptying of the tank.

- 25x30 Oenological from HL 3,2 to HL 7,5

- 40X40 DIN from HL 11 to HL 15.

Allows total emptying of the tank.

- 25x30 Oenological from HL 3,2 to HL 7,5

- 40X40 DIN from HL 11 to HL 15.

Internal pressure and flows are distributed in the best possible way.

- The perimeter structure of the tank is designed to allow easy movement of the tank using forklifts.

- The sizing of the tank allows you to increase the efficiency and yield of the space inside the cellar.

- It is possible to request an "Eco" model of the tank during the estimation phase.

Indispensable optional for the removal of pomace and excellent internal cleaning.

Thanks to its wide opening, it allows easy access for cleaning and removing the pomace.

Helps superior accessibility, loading and the ability to check the inside of the tank.

The increase in temperature stimulates the lactic bacteria, responsible for the malolactic fermentation.

The balanced weight is useful to facilitate a comfortable and risk-free movement of the tank.

Allows you to safely hook and place the ladder on the tank.

Useful for ensuring tartaric precipitation. (part of the thermo regulation kit).

Essential for intuitively knowing the internal temperature of the liquid.

It allows you to limit energy waste by maintaining a stable temperature.

Thanks to a graduated scale, it allows you to view the level of liquid inside the tank.

Indispensable for optimal maintenance of the internal density.

Thanks to its slope, it allows easy cleaning and removal of the pomace.

One of the many solutions for the correct internal cleaning of the tank.

It allows you to easily and safely take small quantities of samples of the content.

It allows an accurate and homogeneous washing of the whole inside of the tank.

¹ Circular hatch mountable up to HL20.

² Rectangular hatch (vertical or horizontal opening)dimension 310x420 up to HL 5 / dimension 405x530 from HL 7,5 to HL 15.

³ Washing ball inlet ¼” GAS thread from HL 3 to HL 5 / inlet ½” from HL 7,5 to HL 15.

- Other available options: Probe holder well / Insulation of the thermo-regulation band (welded or riveted) / Visual level / Motion agitator for valves / Manhole covers (ø200-300-500-600) / Decanter valves / Elliptical hatches / Racking hatch / Digital thermometer / Filler cap / Pressurized tank / Turbine tank washer / Rotating head washing / Thermoregulation plate on manhole cover.

-Tank superimposed on several watertight compartments

- It is possible to request options during the estimation phase which are not mentioned in these pages.

- Many options allow a great saving of time during the production cycles of the product.

- The optionals are specific for every need, ask for any kind of information from our sales department without any problems.

- Tailor-made channels and wells for the removal of process water.

- Automatic fulling system.