Mixing or scraping tanks

Mixing or scraping tanks

CHARACTERISTICS

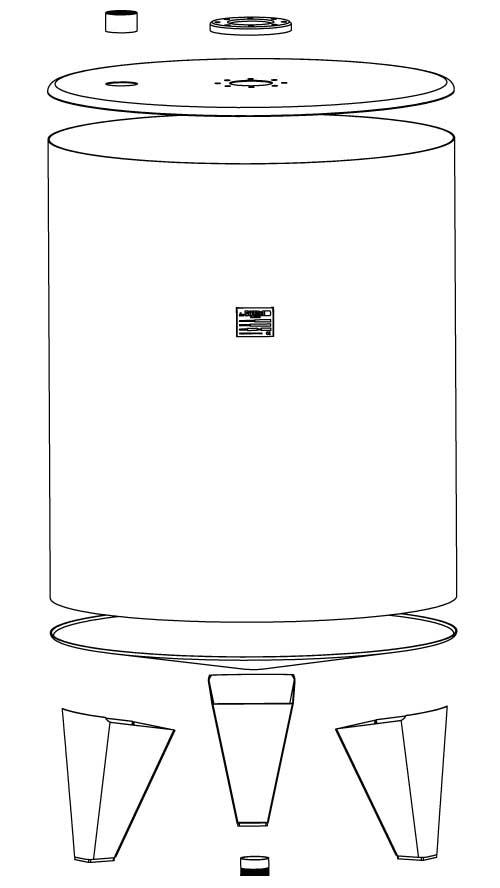

Typical tank used for mixing liquids and not on large or small quantities of product. Extremely simple the predisposition for assembly of motors, agitators and mixers. Controlled product flows, homogenization processes and many other purposes can be generated by means of a propeller connected to the motor.

BENEFITS

Connectable to computerized PLC systems. The mixing cycles, rotation speed, times and many other process variables are programmable. Extremely easy to clean, customizable according to the type of production purpose. Motors, agitators and gearmotors that can be adapted and sized according to the product contained and its chemical-physical characteristics. The rotation system can be completed by fulcrating it at the bottom by means of a compass which allows less vibrations and greater structural stability.

Perfect for cosmetic mixing, it allows a correct homogenization of the product, whether it is in liquid, semi-solid or solid form.

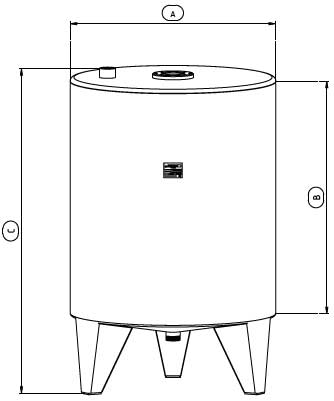

|

Capacity (hl) |

A Diameter (mm) |

B Shell height (mm) |

C Total height (mm) |

|---|---|---|---|

| 5 | 725 | 1500 | 2050 |

| 10 | 955 | 1750 | 2450 |

| 16 | 1195 | 1750 | 2450 |

| 25 | 1275 | 2250 | 2950 |

| 30 | 1275 | 2750 | 3450 |

| 35 | 1275 | 3000 | 3700 |

| 40 | 1595 | 2250 | 2950 |

| 50 | 1595 | 2750 | 3450 |

| 60 | 1755 | 3250 | 4000 |

| 70 | 1755 | 3250 | 3950 |

| 76 | 1800 | 3250 | 3950 |

| 100 | 2040 | 3250 | 3950 |

| 140 | 2400 | 3250 | 3950 |

- The total height of the tank is purely indicative, as it varies according to the types of manhole cover and legs.

- There is the possibility to size the tank in all its parts to your liking. Once the necessary capacity has been identified, it will be possible to adapt the product to your space requirements.

- For any information regarding the availability of products in stock, customized quotes or technical information, you can contact us through the addresses you will find in the appropriate section.

External surfaces

Internal surfaces

External surfaces

Internal welds

External welding accessories

- Recommended for its easy internal washability and unmistakable aesthetic characteristics.

- Finishing normally essential for easy cleaning and homogeneity of shape.

- It is always possible to combine the different types of finishings with respect to those mentioned above to your specific aesthetic and technical needs.

- Specific material for its high resistance to corrosion.

- The difference in the material used derives from specific preservation of particular contents, or from placement environments requiring even higher corrosion resistance capabilities.

Facilitates filling with a classic connection.

- 1 connection from HL 5 to HL 10

- 2 connection from HL 16 to HL 76

- 3 connection from HL 100 onwards

Conveniently cleanable and inexpensive.

Guarantees structural rigidity and helps emptying.

- Reinforcement plate from HL 40 onwards.

Essential for obtaining a safe support surface.

- Nr. 3 up to HL 50.

- Nr. 4 from HL 65 onwards.

Dimensioned according to the motor connection.

It identifies the tank and communicates its main data.

Facilitates emptying with a classic connection.

- 1 connection from HL 5 to HL 10

- 2 connection from HL 16 to HL 76

- 3 connection from HL 100 onwards

- Press-formed sheet metal legs are standard in tanks with a minimum capacity of 300 liters.

- The quantity of legs necessary for a correct sizing is chosen by the manufacturer according to the capacity of the tank.

- The drain valves of the tanks are basic with ball closure type.

In the presence of access possibilities, it is essential to be able to use it to ensure safety.

Safe and simple inspection. Fundamental to be able to operate by eliminating risks.

Specific access for carrying out special procedures and technical inspections.

The balanced weight is useful to facilitate a comfortable and risk-free movement of the tank.

Quick and safe connection according to standardized or customized dimensions.

Sizing of everything that contributes to the correct mixing of the product.

Specific component for certain processes. Allows total mixing of the mass.

Simple and immediate viewing of the content. Extremely easy maintenance and cleaning.

Allows you to view the quantity contained, minimizing the risk of breaking the standpipe.

Essential for intuitively knowing the internal temperature of the liquid.

Thanks to its slope, it allows easy cleaning and removal of the solid fraction.

The increase in temperature stimulates the lactic bacteria, responsible for the malolactic fermentation.

Useful for ensuring tartaric precipitation. (part of the thermo regulation kit).

Thanks to the thermo-insulating material, it allows to limit unnecessary heat losses.

Essential for the correct and simple leveling of the structure.

¹ Loading hatch with safety micron from HL 5 to HL 140.

² Lifting eyebolt standard from HL 10 to HL 140.

³ Stainless steel flanged connections welded or free with flare / aluminum free with flare.

⁴ Adjustable foot M24 up to HL 76 / M30 from HL 100 to HL 140.

- Circular hatch mountable up to HL100.

- Rectangular hatch (vertical or horizontal opening) size 310x420 up to HL 5 / size 405x530 from HL 10 to HL 140.

- Washing ball inlet ¼” GAS thread up to HL 10 / inlet ½” from HL 16 to HL 35 / inlet ¾” from HL 40 to HL 76 / inlet 1”¼ for HL 140.

- Clamp connections

- Other available options: Ladder coupling / Manhole covers (ø200-300-500-600) / Elliptical hatch / Visual level / Retractable visual level / Digital thermometer / Pressurized tank / Roof of various convexities / Total insulation of the tank / Piping or connection pipes / Bottom of various convexities / Deflectors and internal wave breakers / Conical bottom 18 degrees / Load cells / Agitator shovel with marine propeller / Turbine tank washer / Rotating head washing.

- Furthermore, the following systems have been carefully studied and designed: Walkways / Balconies / Ramp and spiral access stairs / Marine ladders / Collapsible inspection staircase / Gates next to loading and unloading areas / PLC for automatic process cycle / Electrical panel / Pumps connected to the tank / Removable grid in sectors, inclined or flat.

- We are at your complete disposal for any type of modification on tanks with connections, reductions and much more, with the sole purpose of improving the quality of your work.

- It is possible to request options during the estimation phase which are not mentioned in these pages.

- The options are specific for every need, ask for any kind of information to our sales department without any problems.

- Customized channels and wells for the removal of process water.

- Automatic fulling system.