Vertical rounded corner tanks

Vertical rounded corner tanks

CHARACTERISTICS

The main characteristic of this product is undoubtedly the structure which used to the best of its possibilities leads to great results. The basic feature is an inclined flat bottom that guarantees cleaning in a simple, easy and fast way.

BENEFITS

Technical and structural efficiency are the keywords. Arranged with a flat bottom inclined towards the door by 4% which, by exploiting the force of gravity, allows easy removal of the solid component of the product. This means that cleaning and access are greatly facilitated. The standard guarantees the possibility of having an off-center ceiling towards the front, allowing convenient access to the tank, avoiding unnecessary exposure and risks on the part of the operator. The umpteenth advantage is given by considering a greater external surface which reserves a greater possibility of positioning any optional.

An indispensable tank for increasing the quality of a wine that can be characterized by technically specific oenological processes such as carbonic maceration or aging on noble lees. This tank allows to increase the exchange surface through a wider bottom and top, increasing the chemical, physical and organoleptic characteristics of the finished product that is processed. In addition, the characteristic pocket for thermo adjustment becomes more easily manageable in practice as a result of larger surfaces in contact with the contents.

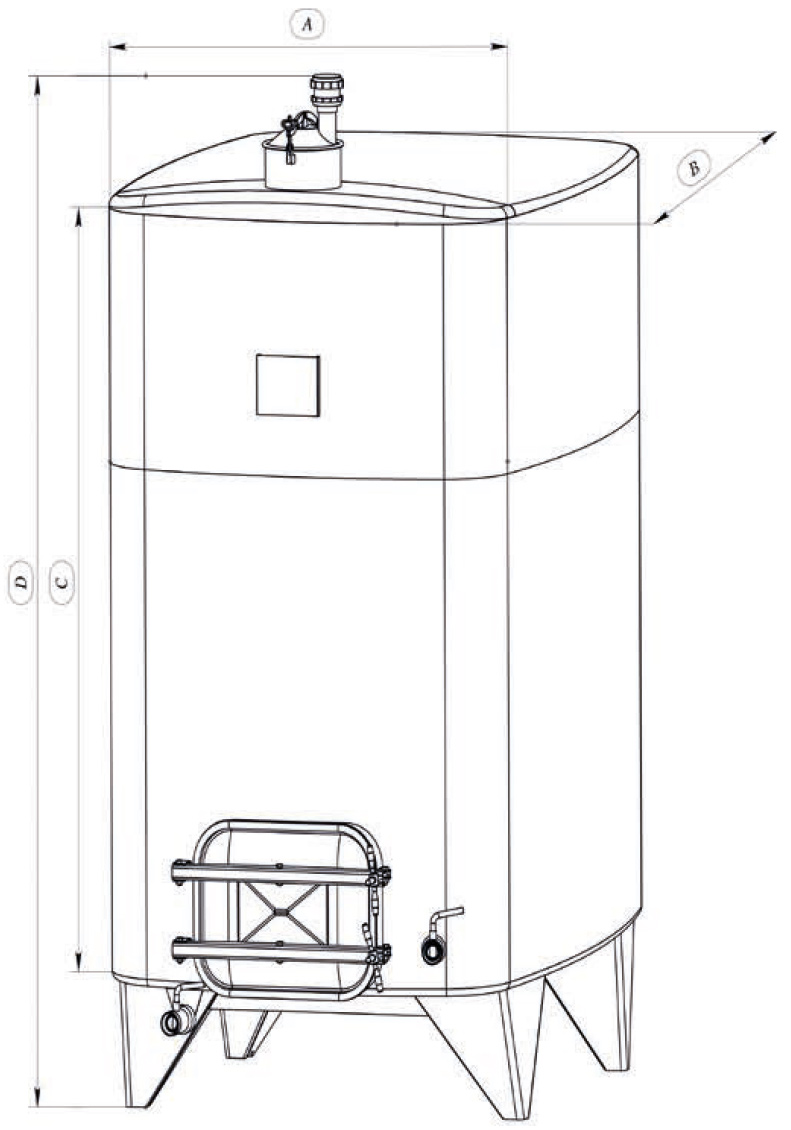

|

Capacity tank (hl) |

A Width tank (mm) |

B Depth (mm) |

C Shell height (mm) |

D Total height (mm) |

|---|---|---|---|---|

| 5 | 750 | 950 | 1000 | 1700 |

| 10 | 750 | 950 | 1500 | 2200 |

| 15 | 900 | 1200 | 1500 | 2200 |

| 20 | 900 | 1200 | 2000 | 2700 |

| 25 | 900 | 1200 | 2500 | 3200 |

| 30 | 1150 | 1450 | 2000 | 2700 |

| 35 | 1150 | 1450 | 2250 | 3000 |

| 40 | 1150 | 1450 | 2750 | 3500 |

| 50 | 1400 | 2000 | 2000 | 2700 |

| 60 | 1400 | 2000 | 2500 | 3200 |

| 75 | 1400 | 2000 | 3000 | 3700 |

| 100 | 1400 | 2000 | 4000 | 4700 |

- The total height of the tank is purely indicative, as it varies according to the types of manhole cover and legs.

- There is the possibility to size the tank in all its parts to your liking. Once the necessary capacity has been identified, it will be possible to adapt the product to your space requirements.

- For any information regarding the availability of products in stock, tailor-made quotes or technical information, you can contact us through the addresses you will find in the appropriate section.

External surfaces

Internal surfaces

External welds

Internal welds

External welding accessories

- Recommended for its easy internal washability and unmistakable aesthetic characteristics.

- Finishing normally essential for easy cleaning and homogeneity of shape.

- It is always possible to combine the different types of finishings with respect to those mentioned above to your specific aesthetic and technical needs.

- Specific material for its high resistance to corrosion.

- The difference in the material used derives from specific preservation of particular contents, or from placement environments requiring even higher corrosion resistance capabilities

The double effect avoids major damage and risk of implosion.

Essential for viewing the contents of the tank.

- ø300 up to HL 5.

- ø400 from HL 10 onwards.

Classic shape, prevents the formation of air bubbles

It identifies the tank and communicates its main data.

Wide and easy access for cleaning and removal of pomace.

- Vertical or horizontal opening.

- Size 310x420 up to HL 5.

- Size 405x530 from HL 10 onwards.

Guarantees rigidity; structural and helps emptying.

Allows partial emptying of the tank.

- 25x30 Oenological from HL 3,2 to HL 7,5

- 40X40 DIN from HL 11 to HL 41

- 50X50 Din from HL 51 onwards.

Allows total emptying of the tank.

- 25x30 Oenological from HL 3,2 to HL 7,5

- 40X40 DIN from HL 11 to HL 41

- 50X50 Din from HL 51 onwards.

Essential for obtaining a safe support surface.

- The sloping flat bottom generally with a slope of 4% allows an easy cleaning phase thanks to the help of gravity.

- Its characteristic shape offers a perfect response to optimize spaces with an excellent structural complex.

- The drain valves of the tanks are basic with ball closure type.

ø200, ø300, ø500, ø600 allow convenient loading access and easy inspection.

The balanced weight is useful to facilitate a comfortable and risk-free movement of the tank.

Allows you to safely hook and place the ladder on the tank.

Indispensable for optimal maintenance of the internal density.

One of the many solutions for the correct internal cleaning of the tank.

Indispensable optional for the removal of pomace and excellent internal cleaning.

Characterized by an internal opening, ensuring a perfect hermetic closure.

It allows you to easily and safely take small quantities of samples of the content.

Thanks to a graduated scale, it allows you to view the level of liquid inside the tank.

Indispensable for optimal maintenance of the internal density.

The filling of the tank is made easier thanks to a classic connection.

Essential for intuitively knowing the internal temperature of the liquid.

Essential for intuitively knowing the internal temperature of the liquid with digital display.

It allows an accurate and homogeneous washing of the whole inside of the tank.

Essential for the correct and simple leveling of the structure.

¹ Lifting eyebolt standard from HL 10 to HL 100.

² Circular hatch mountable up to HL100.

³ Retractable visual level ø16 up to HL 15 / from HL 20 to HL 30 ø20 / ø24 to HL 100.

⁴ Loading shaft 1 "GAS from HL 5 to HL 10/2" GAS from HL 15 to HL 100.

⁵ Adjustable foot M24 up to HL 100.

- Other available options: Bordered flat bottom / Pressurized tank / Piping or connecting pipes / Total insulation of the tank with stainless steel or aluminum coating / Turbine tank washer / Rotating head washing.

- Furthermore, the following systems have been carefully studied and designed: Walkways / Balconies / Ramp and spiral access stairways / Marine ladders / Gates next to loading and unloading areas / PLC for the automatic cycle of processes / Pumps connected to the tank / Removable grid in sectors, inclined or flat.

- It is possible to request options during the estimation phase that are not mentioned in these pages.

- Many options allow a great saving of time during the production cycles.

- The options are specific for every need, ask for any kind of information to our sales department without any problems.

- Tank superimposed with several watertight compartments.

- Customized channels and wells for the removal of process water.

- Automatic fulling system